ONE TECHNOLOGY, MANY DIFFERENT CATEGORIES

At Biocals Plastics, for many years we have been serving a large number of companies that trust our experience and know-how to produce plastic items through their molds for themselves.

Plastic parts from various application fields, such as :

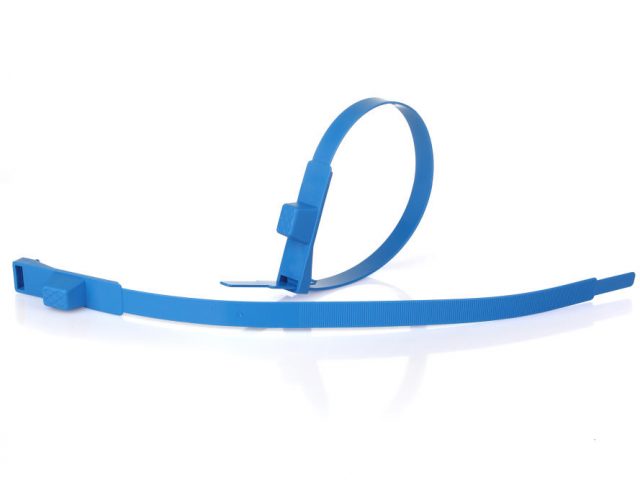

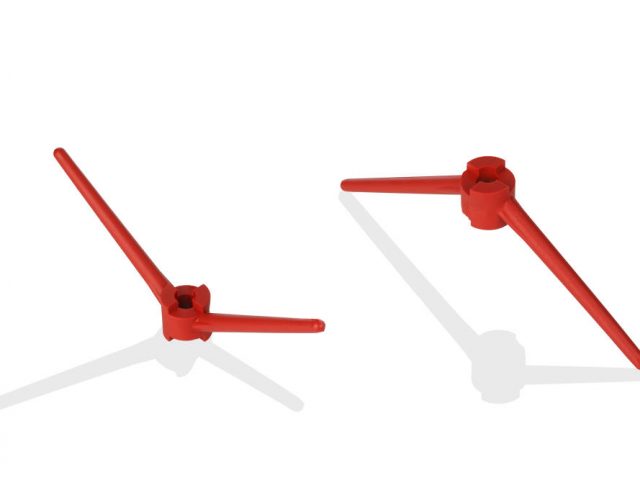

- Sailing market items

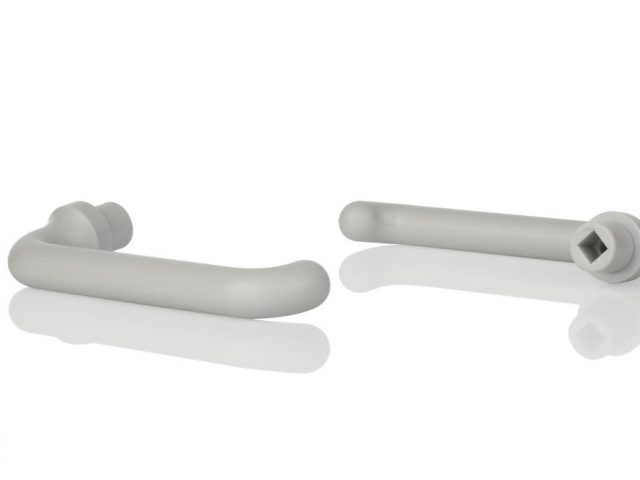

- Plastic parts for Aluminum Systems

- Plastic parts of medical beds.

- Professional refrigerator mechanism components

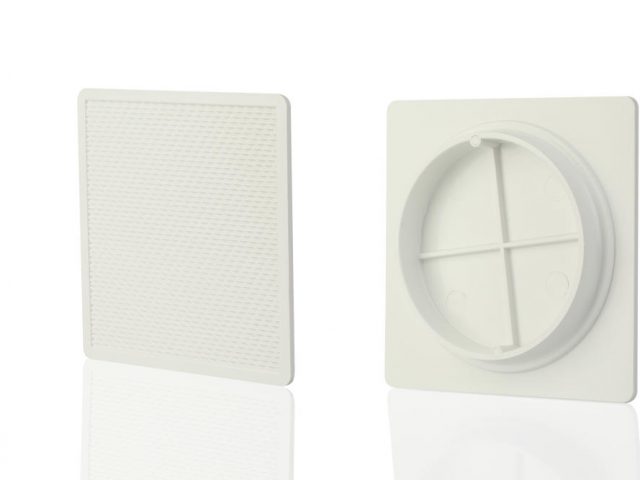

- Plastic parts for swimming pools.

- Accessories for the pharmaceutical industry and medical supplies.

- Advertising promotion objects

- Complete garment hanging solutions for industries in the field of clothing.

- Agricultural machinery plastic components

We use polymers such as:

- P.P with fiberglass

- ABS

- GPPS / HIPS

- POM

- PA + Fiberglass

- PVC

- PU / PU + Fiberglass

- PMMA

- PC

- PE

- SAN

- PC/PBT

Choosing the right polymer depends on several factors that the customer requires:

- The mechanical strengths, the temperature point that we want each plastic object to withstand, its transparency, impact resistance & tension, elasticity, contraction and expansion depending on temperature, life expectancy etc

- Moreover, depending on the requirements of each customer, we use additives in each material, eg. resistance to contact with sea water or swimming pool water. Additives for the continuous presence of the object under the sun and its resistance to UV radiation or to be a self-extinguishing material in case of fire.

Do not hesitate to contact us to discuss the possibility of producing your product through your own mold.